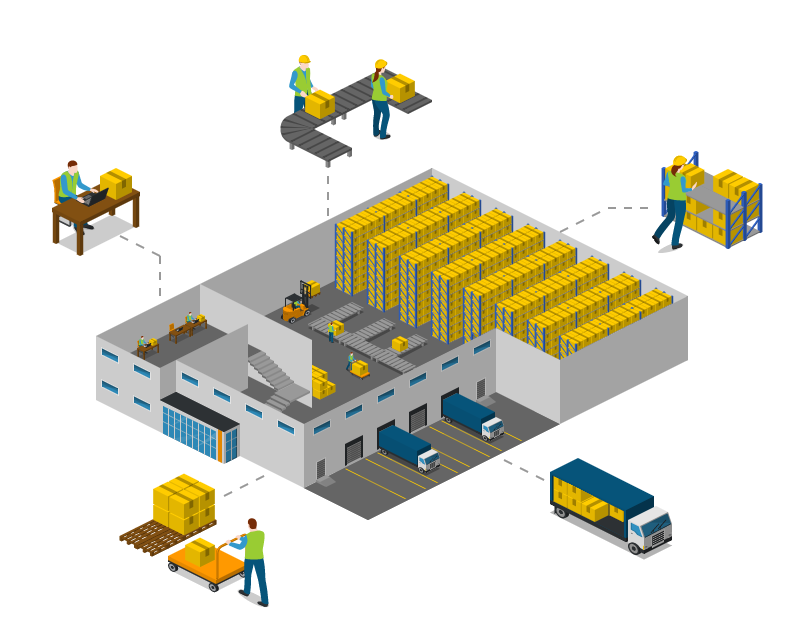

You can see how various elements were brought into the warehouse floor plan to facilitate efficiency in this warehouse model. In the ecommerce pick-pack-and-ship warehouse layout below, notice where the aisles (A) for product storage are placed.

Remember-every business need is different, so while you can learn from other warehouse layouts, you must keep your unique needs foremost in mind.

#Warehouse blueprint background manual

Here’s an explanation of when to use each of these popular equipment options: Pallet RacksĪ manual forklift scale weighs and transports heavy loads.

Amazon, Home Depot, and Lowesare also good sources for standard equipment-especially when needed in small quantities. Other options include buying equipment from importers such as Alibaba, which often offers warehouse gear at steep discounts. Purchasing preowned equipment is a popular and accessible alternative to buying new hardware-just make sure the condition and equipment type suit your facility’s needs. Your warehouse storage equipment can be purchased through a specialized dealer in your area. None, usually used on shelves, carts, and/or workstations Varies, common allowance is pallet size: 40” x 48” Create Production Zones & Workflow AreasĬommon Sizes and Space to Allow in Your Warehouse Layout For example, a forklift will need more space than a pallet jack. Step 2: Allow sufficient space so that any equipment used-from hand trucks to forklifts-can navigate the warehouse aisles easily.Īgain, this will vary greatly depending on the products you sell, as different types of products require different handling equipment-which, in turn, affects your aisle spacing.You can see what this layout looks like in the image below. Storage spaces, while equally important, are secondary in your plan-their locations are dependent on where you position your equipment.įor example, if you run an ecommerce company that stocks and ships goods, your key units would be pallet racks and metal shelving. Whatever your key units are, you need to identify and place these elements on your plan first. A business’s key warehouse units, such as manufacturing equipment or workstations, will vary based on the primary goals of the facility.

These are the things that take up most of your space and/or are the center of your production zones.

0 kommentar(er)

0 kommentar(er)